SMT-01 / SMT-02 / SMT-02H / SMT-03 Series

The regulators of the SMT-01, SMT-02, SMT-02H and SMT-03 series are microprocessor-based, programmable controllers intended for use in milk coolers. The casing of these regulators is adapted for panel mounting. They differ from each other in the way of output exits. SMT-02H regulator is additionally sealed, which prevents moisture getting inside the casing.

SMT-01

outputs: using disjoint connectors.

SMT-02

outputs: power supply cable and sensor permanently mounted to the regulator, output of the flap end sensor, made using a disjoint connector.

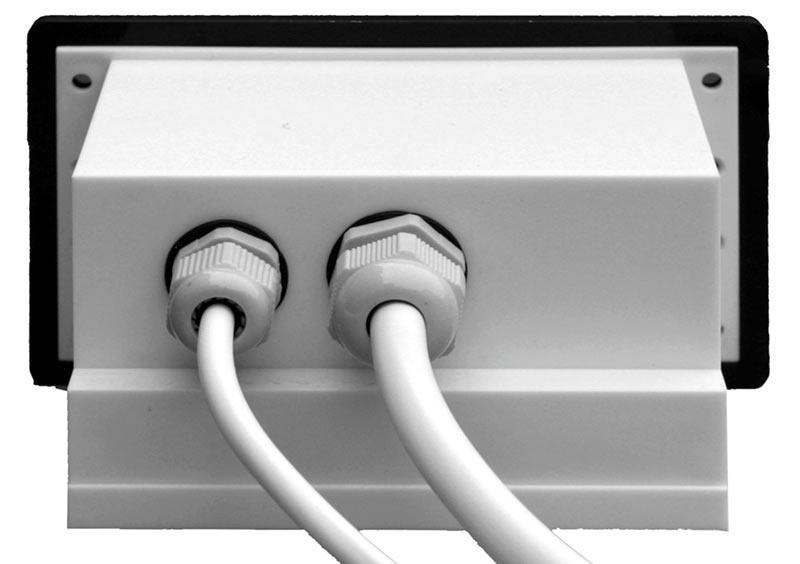

SMT-02H

outputs: power supply and control cable and sensor permanently installed in the regulator and lead out through glands. No output of the flap sensor. The casing parts (front and back) are sealed to each other.

SMT-03

outputs: using the connectors to screw the wires.

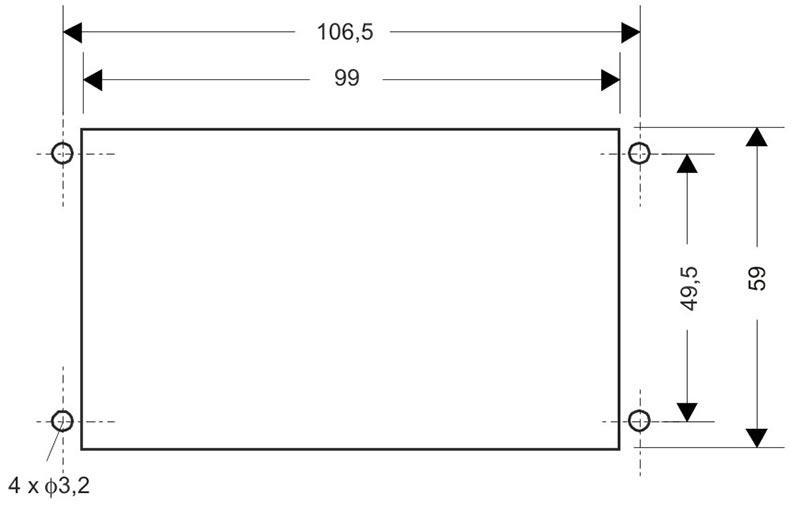

Mounting hole of the casing.

Thanks to the universality of these regulators, other applications are also possible. An example

of another application is the ability to set the regulator as a heating controller and adapt it to control

the heating system. In this case, you can also use the fan control (in all kinds of driers). The factory settings of the regulator enable its quick and direct use for most standard devices.

REGULATOR FUNCTIONS:

-

Selecting the regulator's operating mode: refrigeration mode, heating mode.

-

Measurement and display of measured temperature with a resolution of 0.2 ° C.

-

Controlling the unit depending on the measured temperature with a resolution of 0.2 ° C.

-

The stirrer or fan control enables the implementation of the following variants of this control (depending on the settings made):

automatic work- the stirrer (fan) works cyclically, regardless of the operating condition of the unit (heating system)

the stirrer (fan) works continuously during the operation of the unit (heating system), at the moment of switching off the operation of the unit, the stirrer switches to cyclical operation

- the stirrer (fan) works only when the unit (heating system) is switched on

- switched off stirrer (fan) operation

manually triggered /b>work:- switching on the continuous operation of the stirrer (fan)

- switching on the stirrer (fan) operation for a strictly defined time

-

Visualization of the operation status of the unit (heating system) and stirrer (fan).

-

Blocking the operation of the stirrer (fan) and the unit (heating system) when the flap of the milk cooler tank opens (actuation of the limit switch).

-

-

Memory of the maximum and minimum temperatures throughout the regulator's work cycle. This function is combined with the possibility of temporally delaying the recording of temperature data

to the regulator's memory since its activation. -

Alarm (visual and audible) which signals exceeding the set temperature range. This function is connected with the possibility of delaying the time of switching on the alarm system of the regulator from the moment of its activation./p>

-

Supervision and signaling of the measuring sensor damage.

-

Securing the installer's settings with a password.

-

Limitation of the temperature control range.

-

Delayed shutdown of the unit after opening the milk chiller flap.

REGULATOR CONTROL OUTPUTS:

-

unit (heating system) control output

- stirrer (fan) control output

REGULATOR CONTROL INPUTS:

-

temperature sensor input

- limit switch input